FoRM(Fabrication & MaTERIALS) 2022- 2024 UCLA

Berfin Ataman - Lecturer || Krista Ramirez - TA 2024 | Ariel Uzal- TA 2023 | Don Edler - TA 2022

VESSELS

Students design a vessel using traditional wood working tools as well as the laser cutter. They come up with a concept as to what this vessel is and are free to fabricate it with a given size contraint.

Featured Student Work: Navya Duggirala, Ian Wang, Yuko Ito, Jatearra Richie.

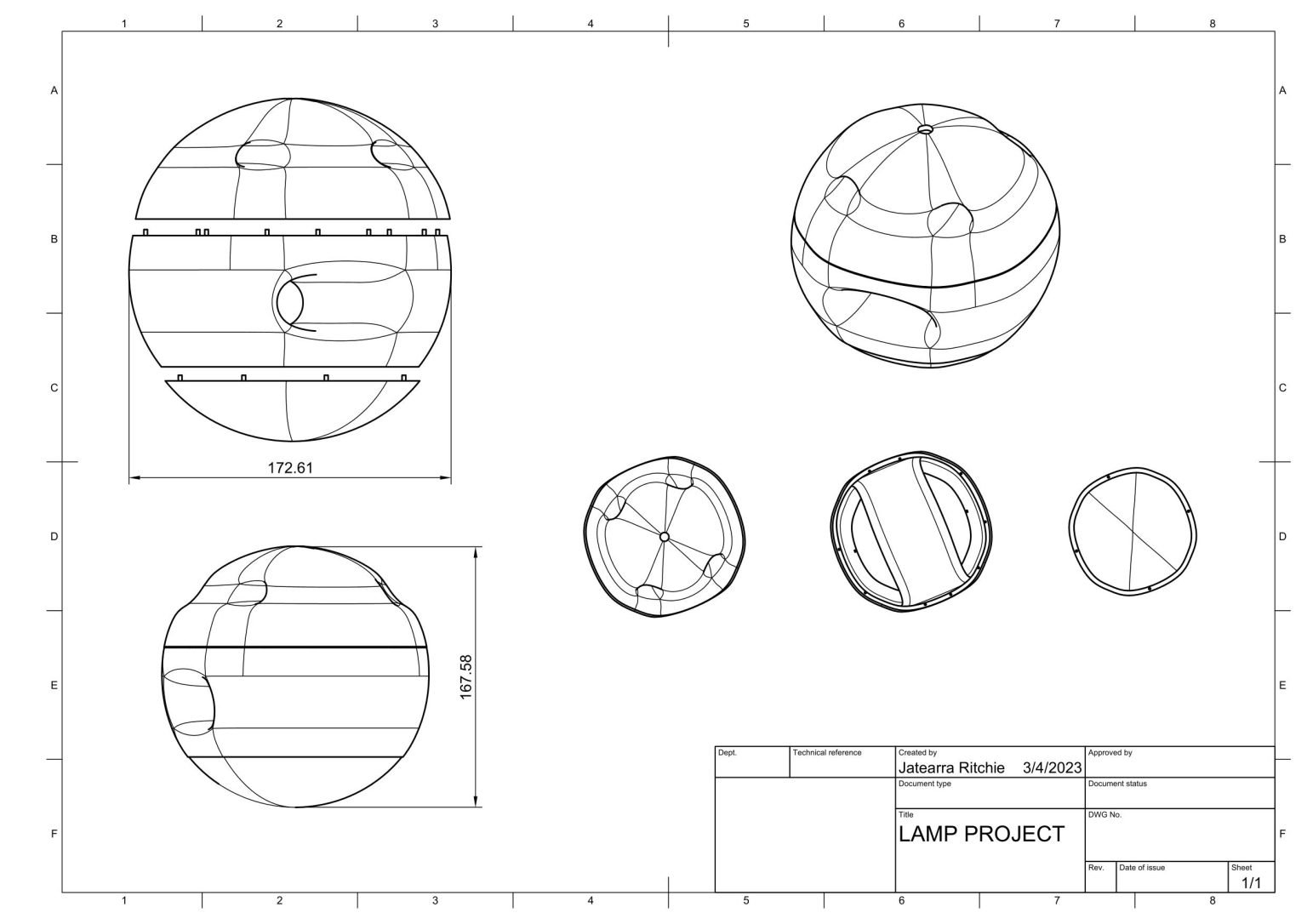

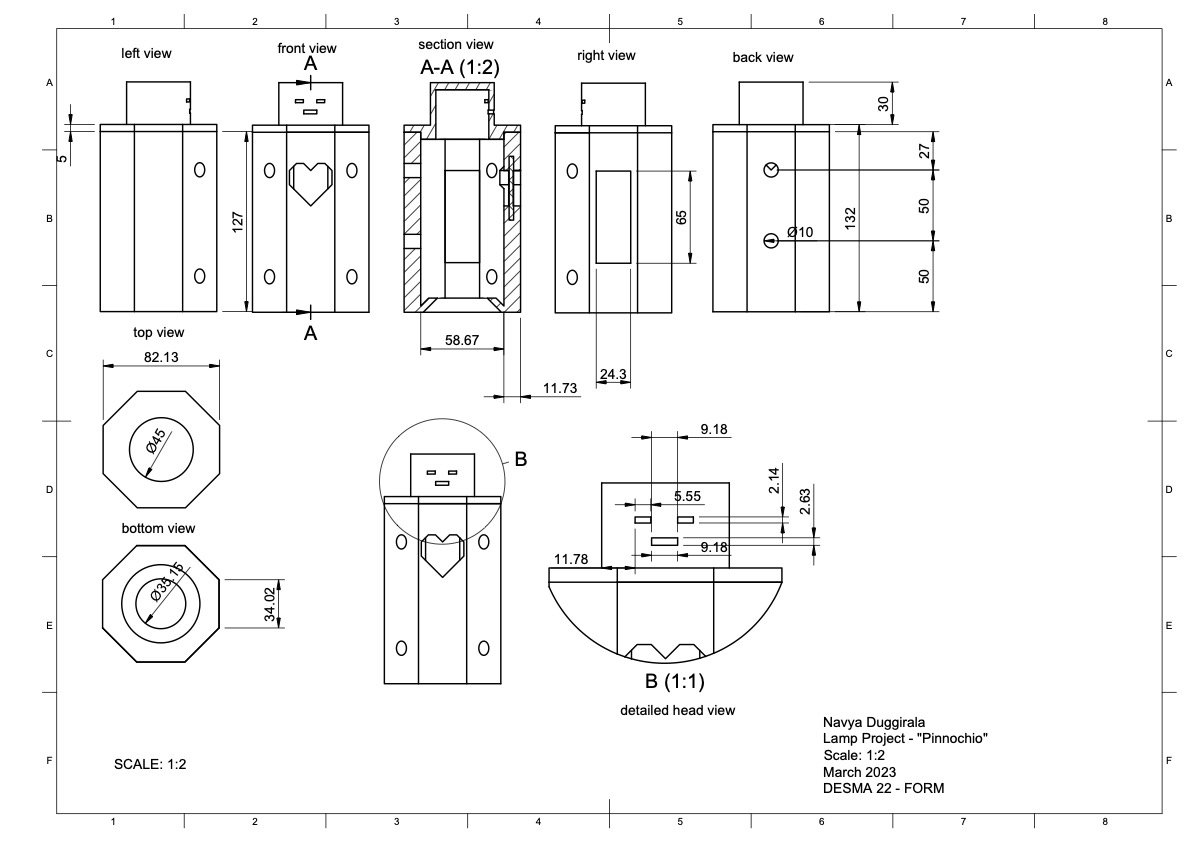

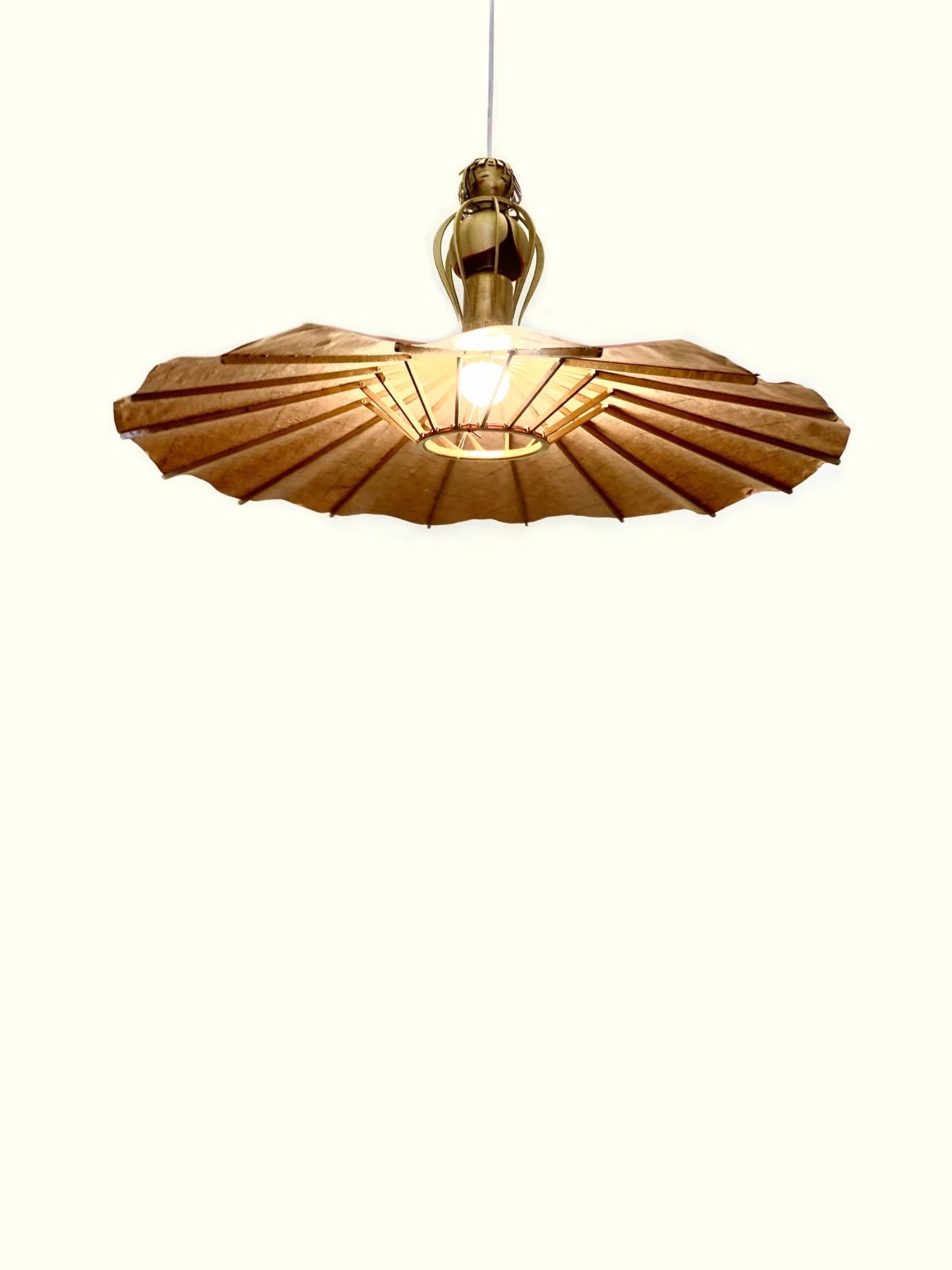

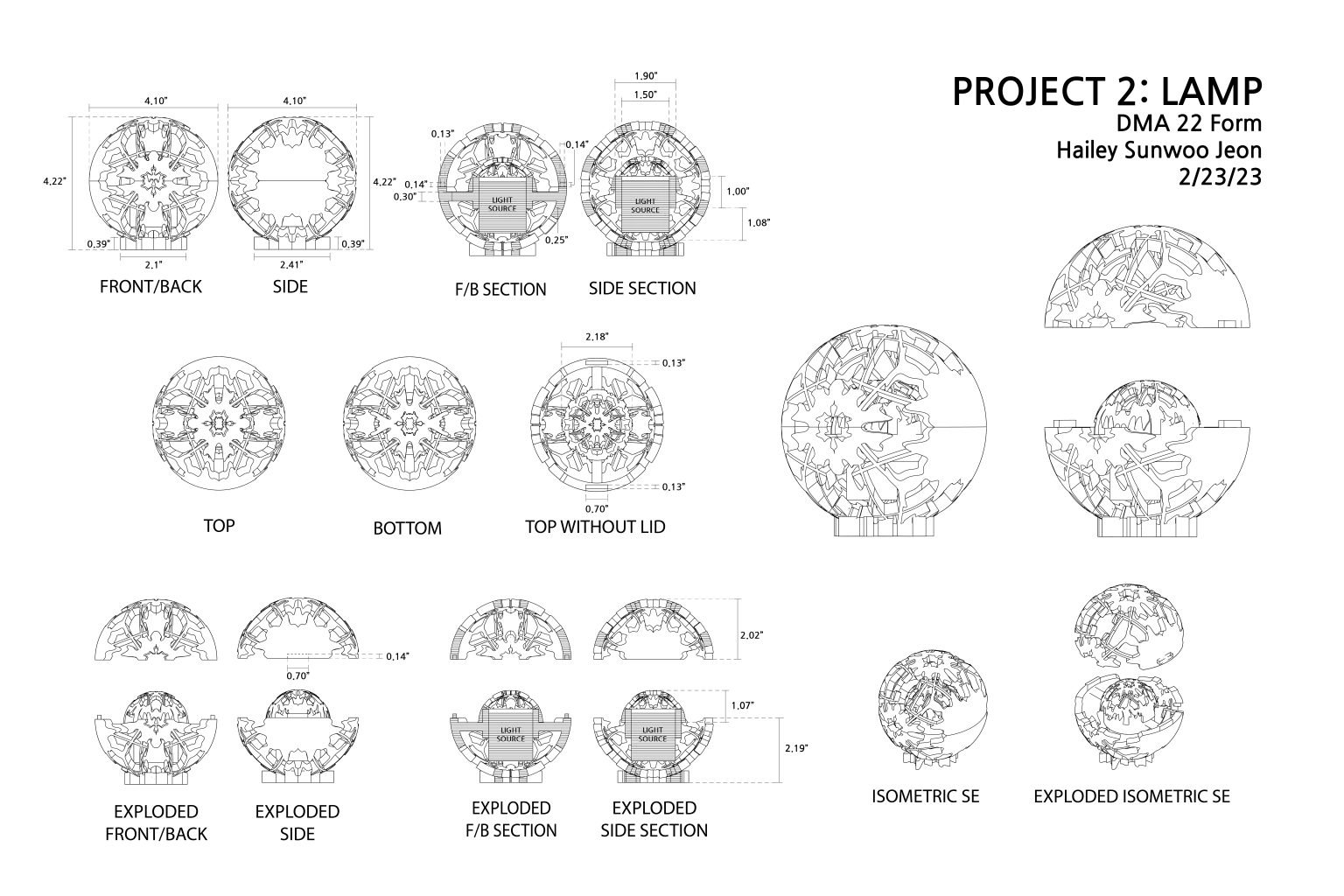

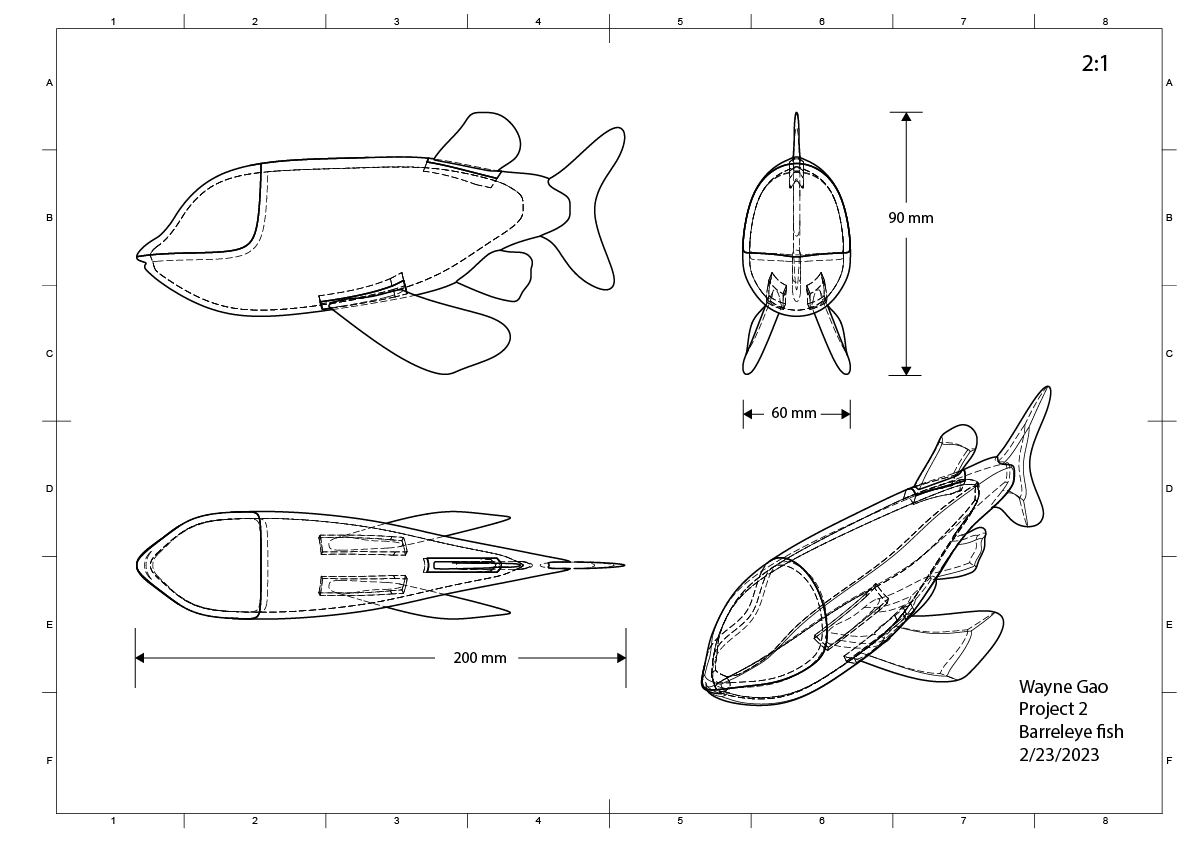

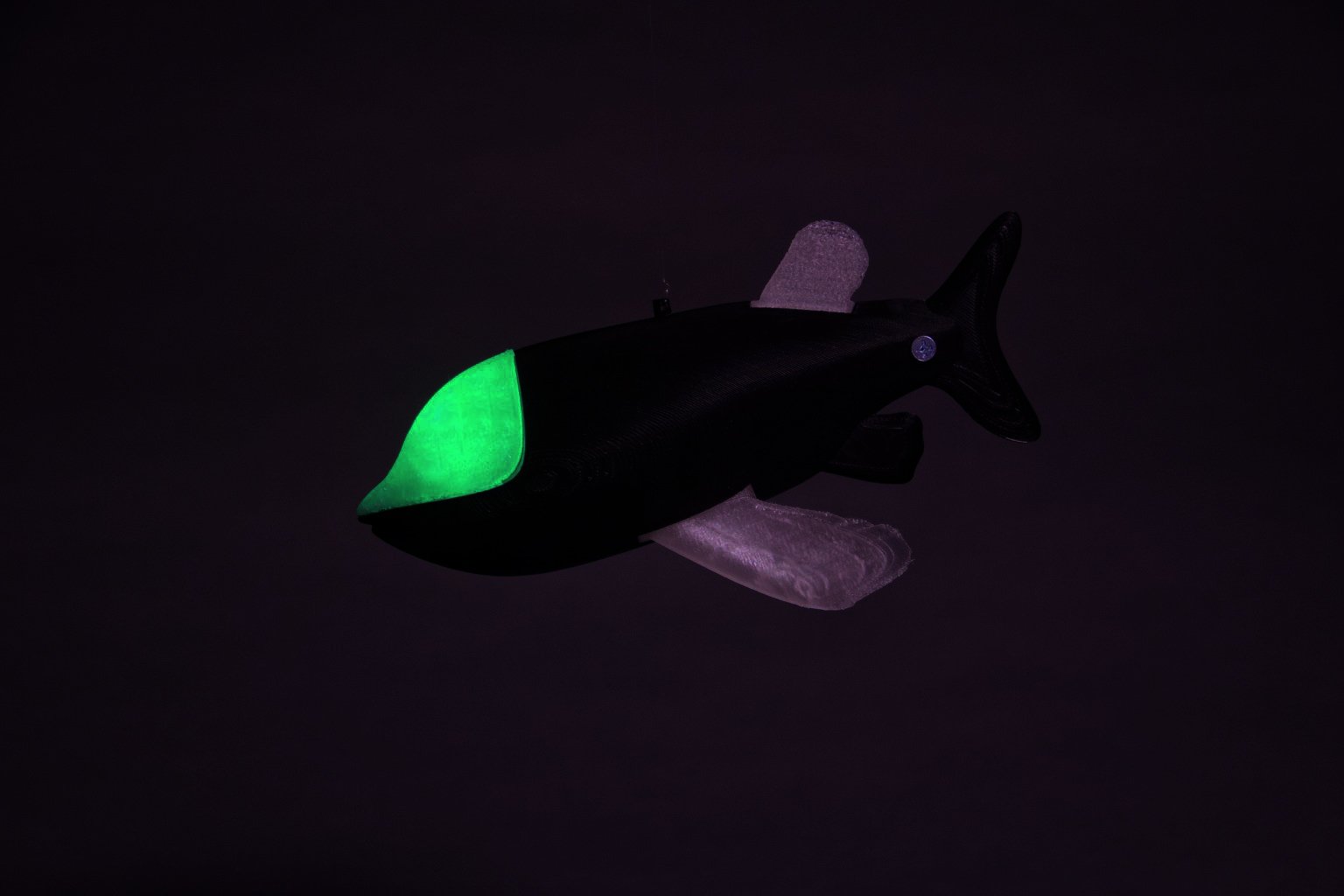

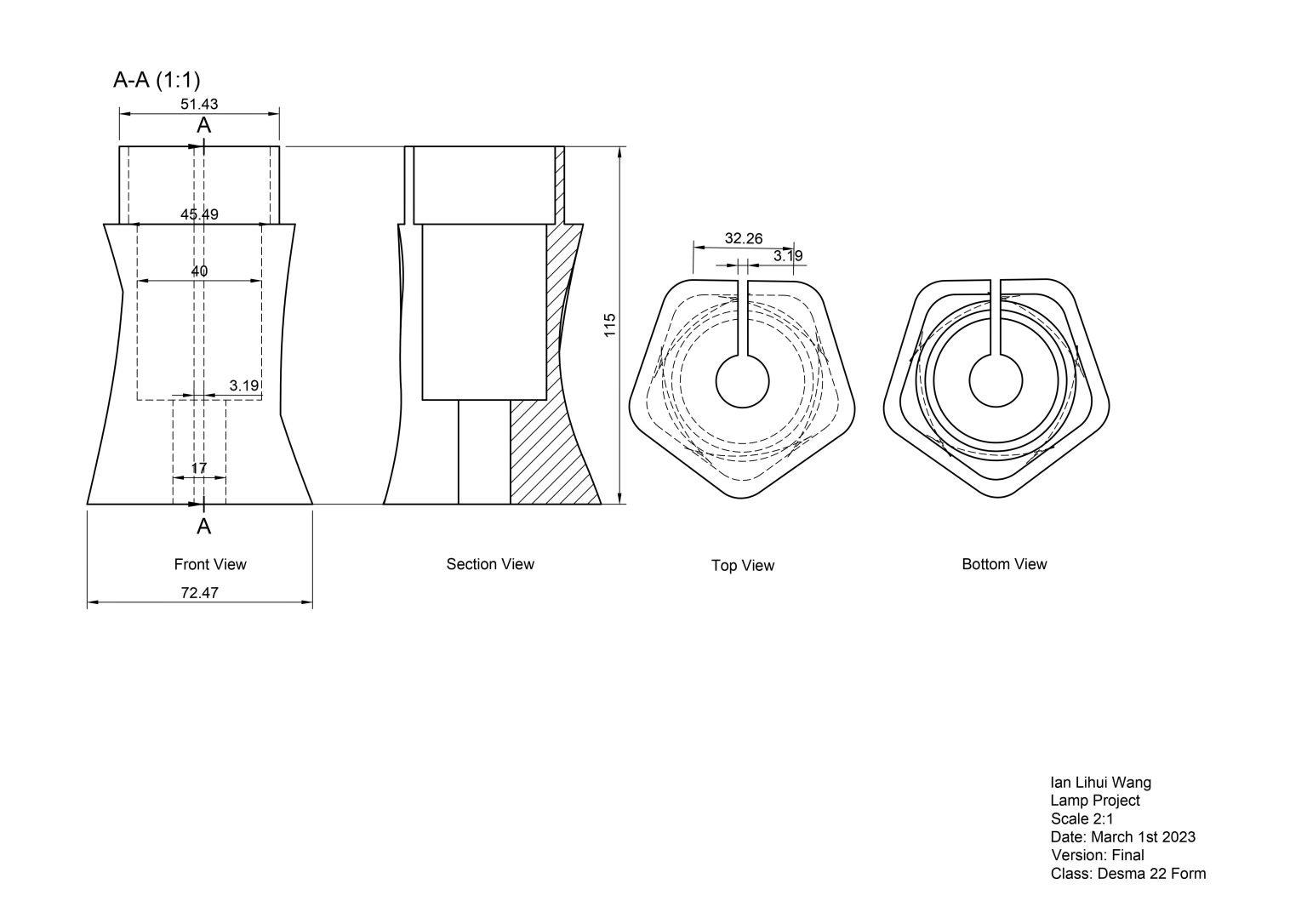

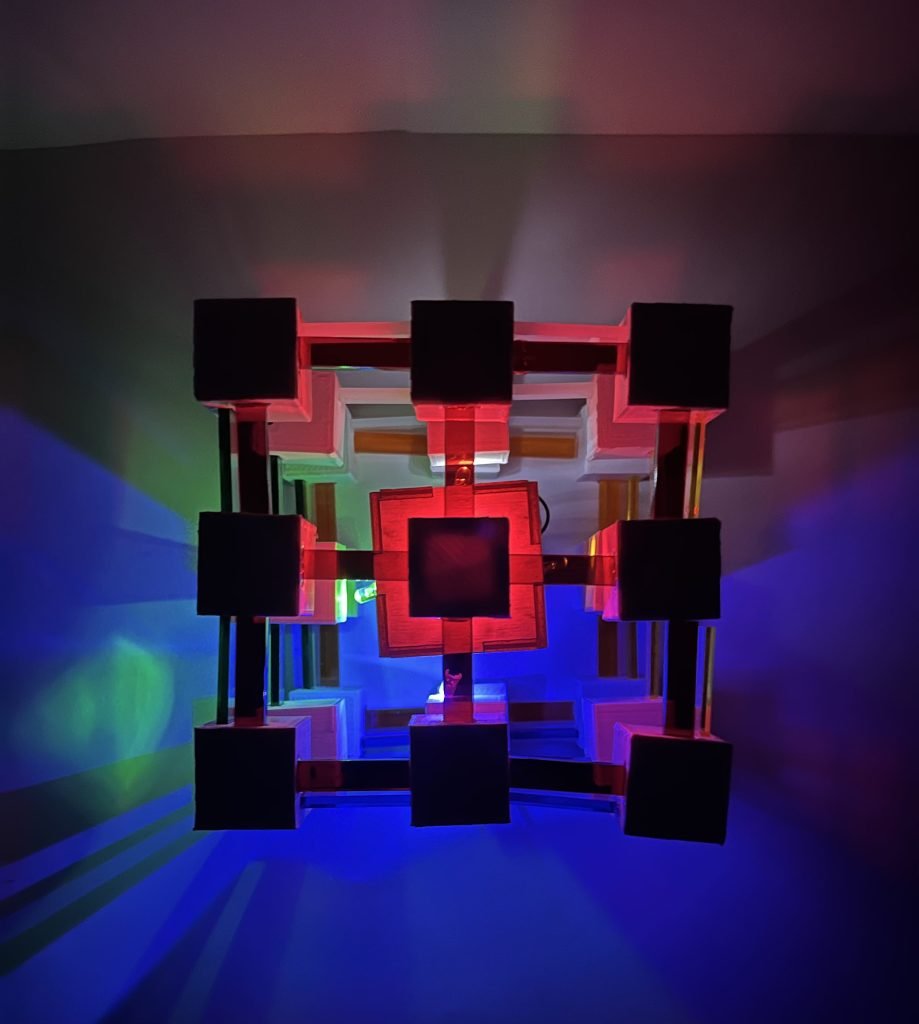

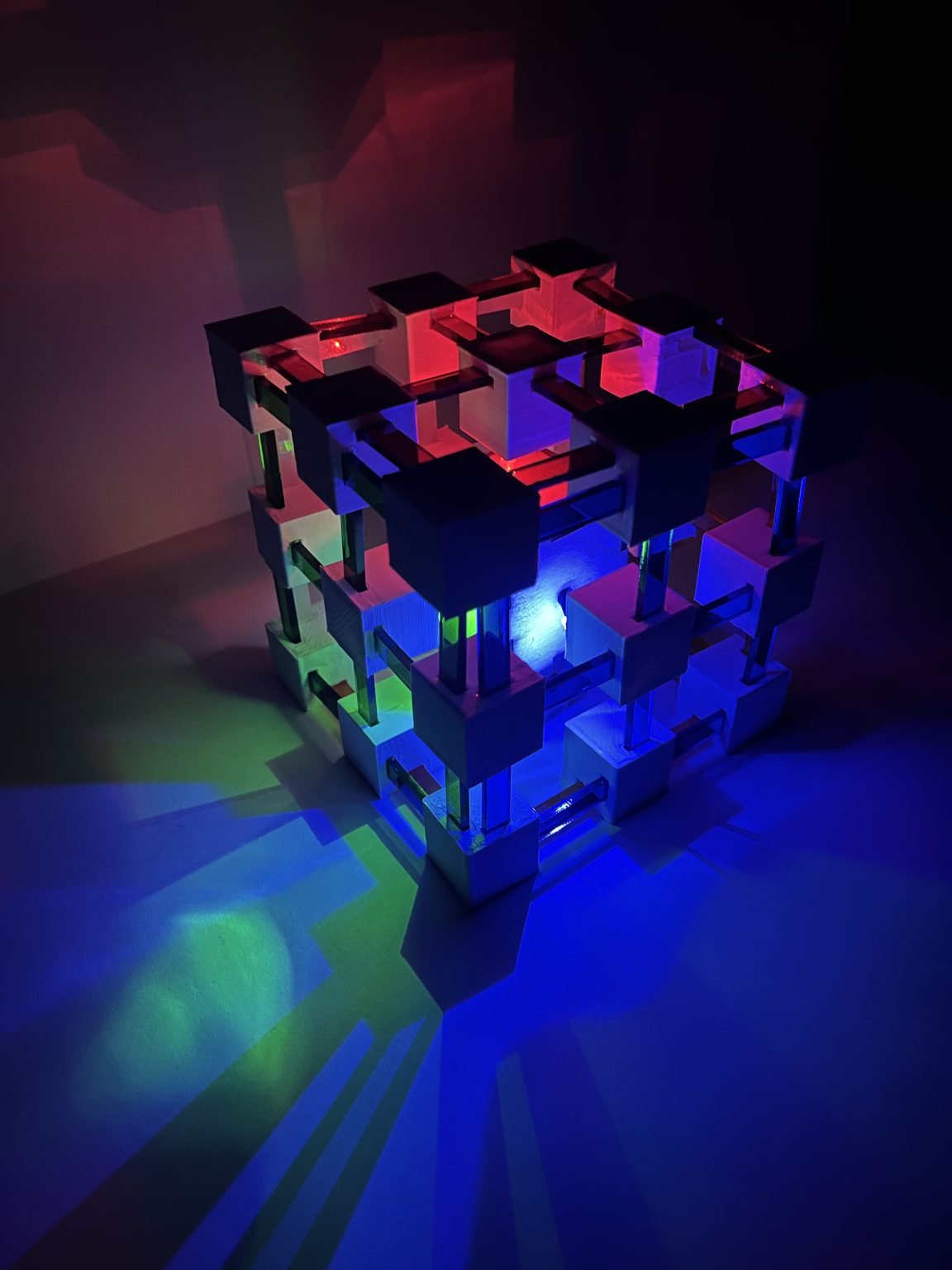

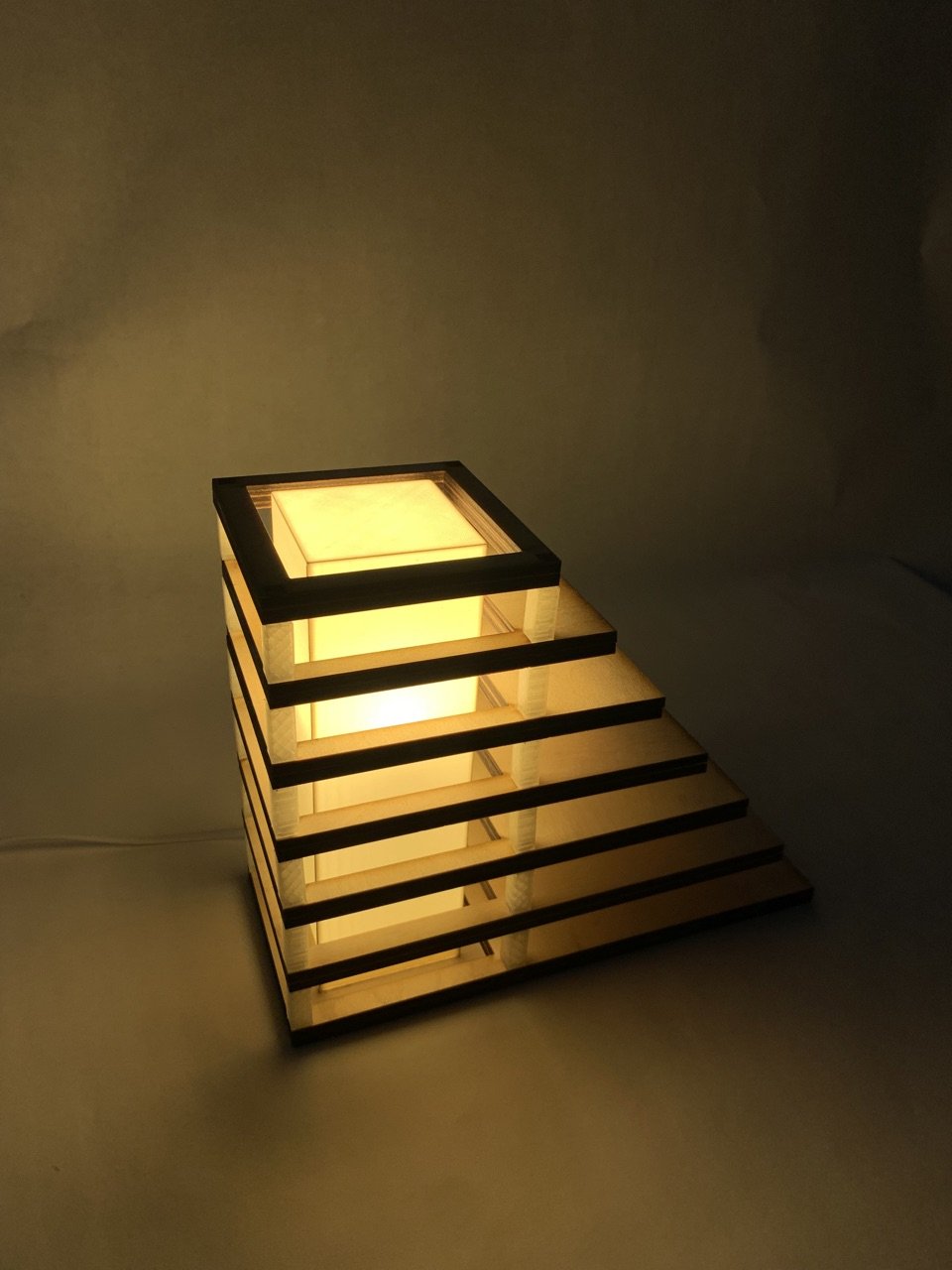

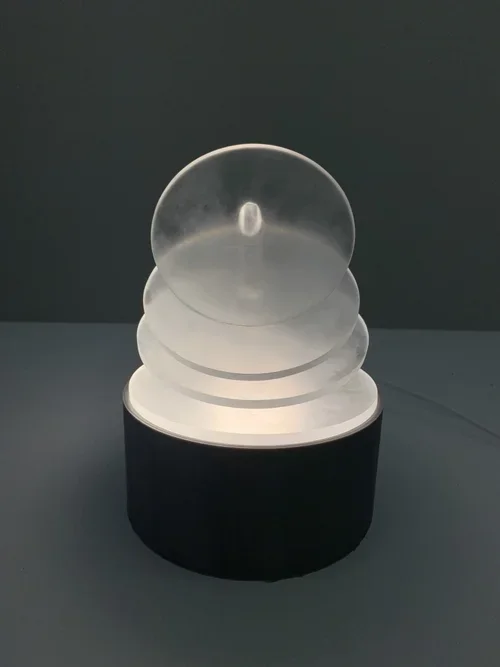

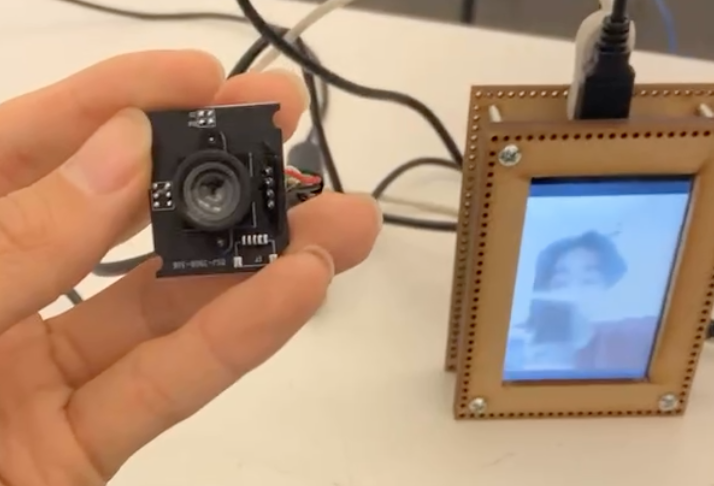

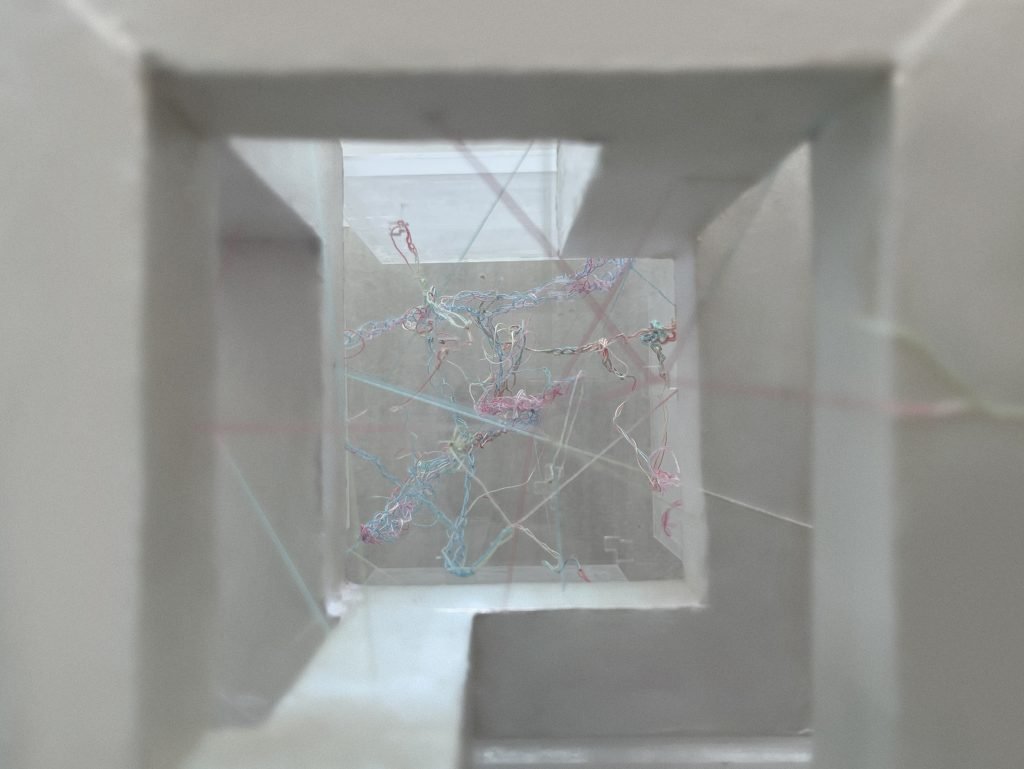

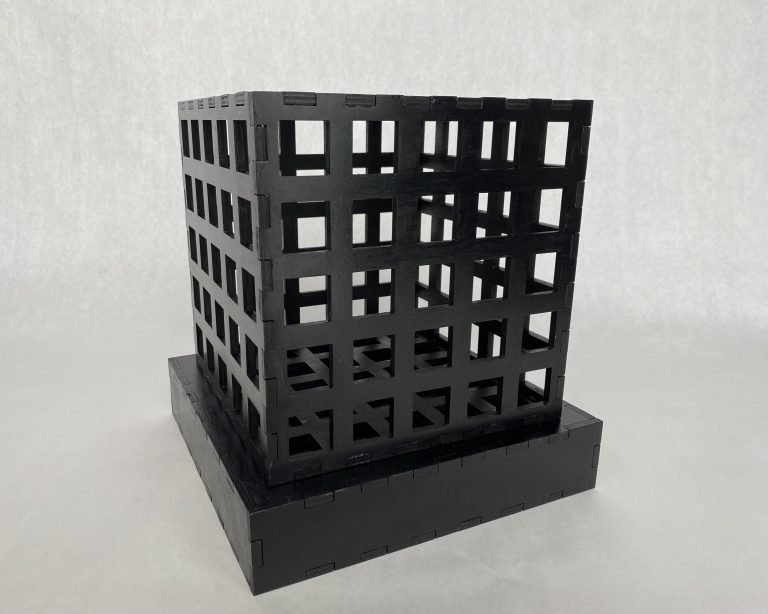

LAMP DESIGN (Additive subtractive process) 2022- 2024

Students developed a design concept and modeled a corresponding form using CAD, translating their digital models into physical objects through the digital fabrication workflows introduced in class. Using real world measurements and an understanding of material tolerance, students designed and fabricated a custom lamp body that fit onto a provided light fixture through a pressure fit connection.

The project asked students to consider how form, material, and fabrication method could shape the behavior of light by filtering, diffusing, or directing it, and how the resulting lamp could alter the surrounding space. Students modeled their designs in Fusion 360 and prepared files using workflow specific software. Lamp bodies could be fabricated using materials including wood, acrylic, PLA, or other suitable media, with tolerances determined through testing of the chosen fabrication process.

Featured Students: Hailey Jeon, Navya Duggirala, Wayne Gao, Ian Wang, Eric Zhou, Jatearra Richie, Laura Grombone,Sarah Chang, Maris Mancinelli, Lauren Villanueva Dan Chuang

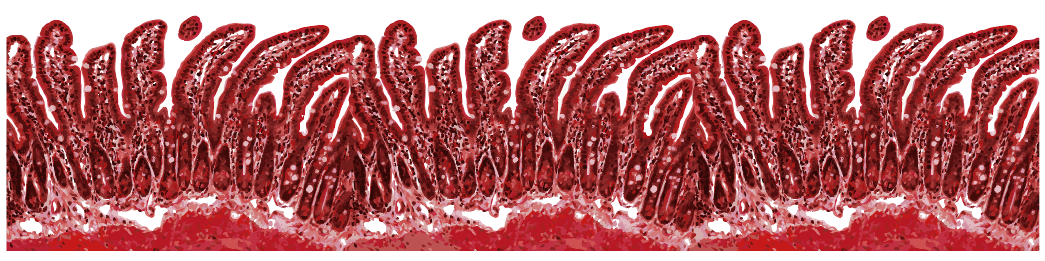

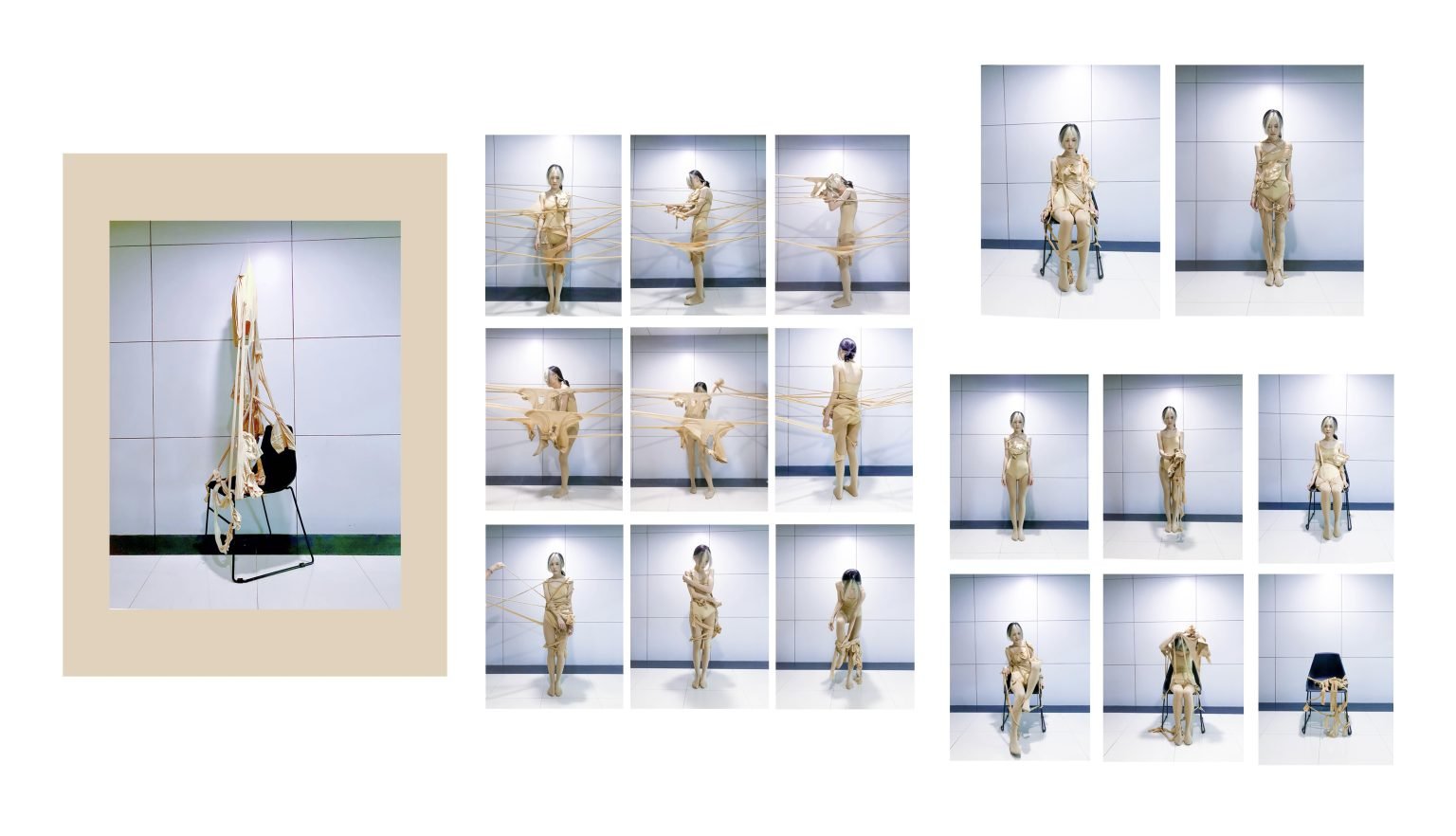

WEARABLE/ SOFT SCULPTURE 2022- 2024

Students made a wearable or soft sculpture. Wearables were required to fit the maker or their friend in class. They could use wood, 3D printing, fabrics, and plastics. They submitted initial drawings, paper patterns, muslin(Prototype), and the final piece. Soft sculpture pieces were required to use sewing machines or other techniques we used in class, like 3D printing and CNC milling. They were required to create 3D volumes with the piece using stuffing, different ways of pattern-making 3D printing, and creating wood structures to hold softer materials. They tuned in Paper pattern, Prototype, and Final piece.

Featured Students: Shenyang Zhao, Laura Grombone, Navya Duggirala, Lauryn Illasco, Yugo Imanashi, Yilin Zhu

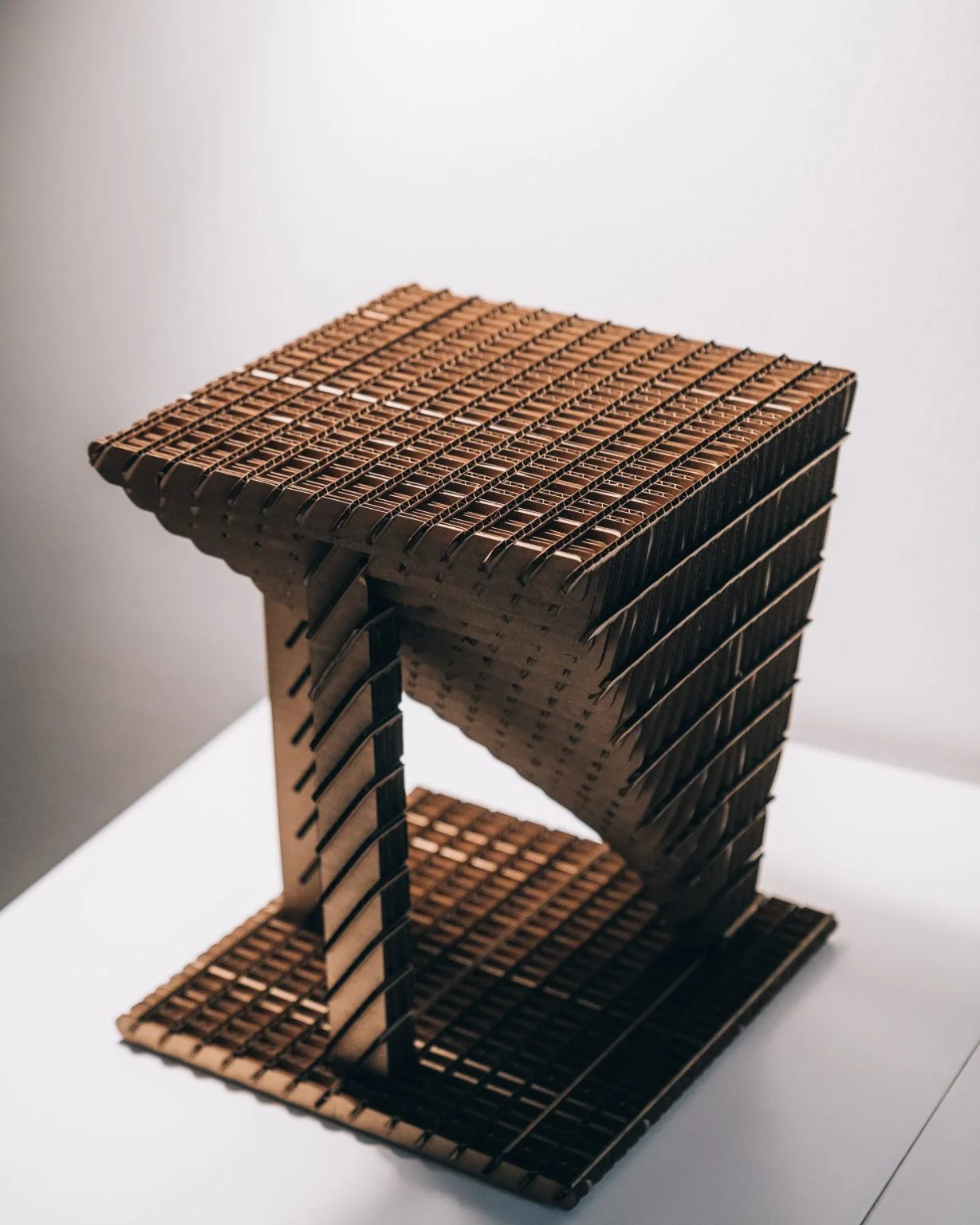

CardBoard Chair Exercise

This was a quick exercise for students to gain fluency in CAD, slicing tools and laser cutting. Over two classes they were instructed to build a stool. Their stool had to be made of cardboard, be able to carry the weight of a person.

Featured Students: Dan Chuang, Yugo Imanishi

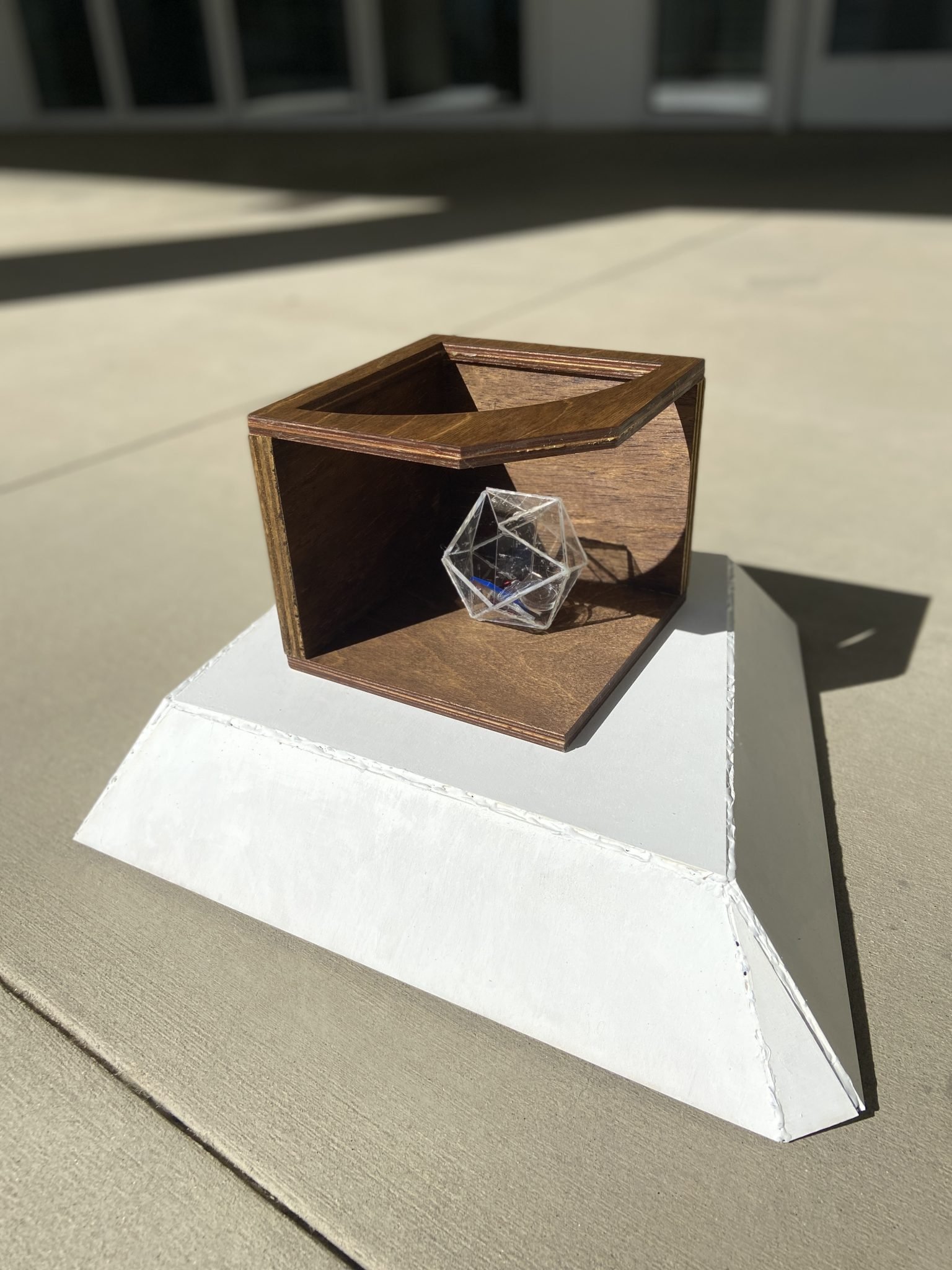

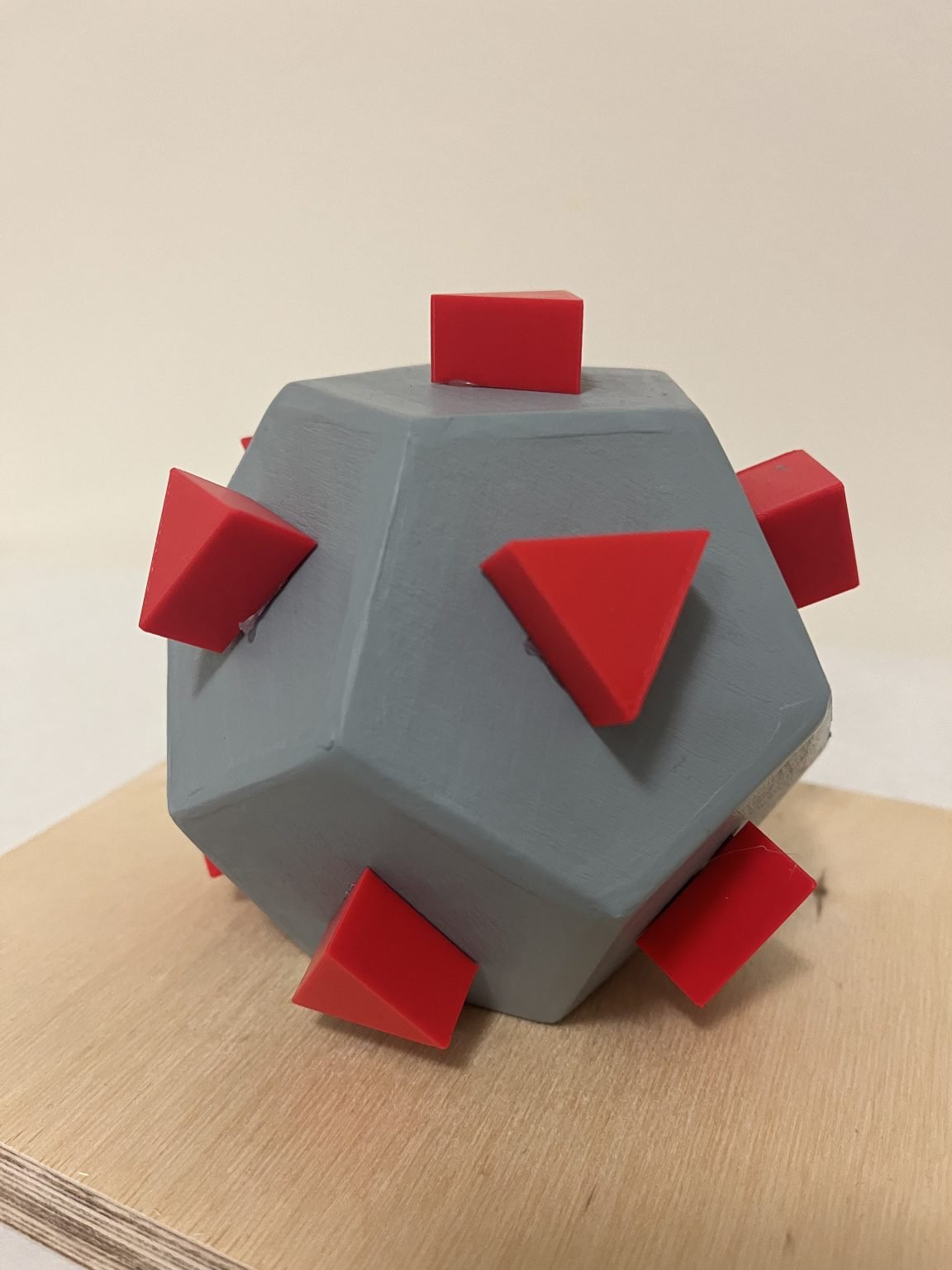

POLYHEDRON& PEDASTAL 2022

Goals: Develop an understanding of technical drawing/ drafting on paper and in Fusion and an understanding of the shop tools. Design a polyhedron (a geometric 3D form with only flat, straight sides) and a pedestal (a rectangular or square box) that fits the scale of your polyhedron. If you are making your polyhedron using woodworking techniques. You can think about unusual ways of creating a pedestal.