Keywords | Underwater Vehicles, Energy Systems, sustainable fuels

Team | Berfin Ataman, Johan Maysonet, JohnByers, Kanglin Kong, Matthew Groll, Ottavia Personeni, Tyler Nagashima, William Cruz

Link to white paper and sponsor draft

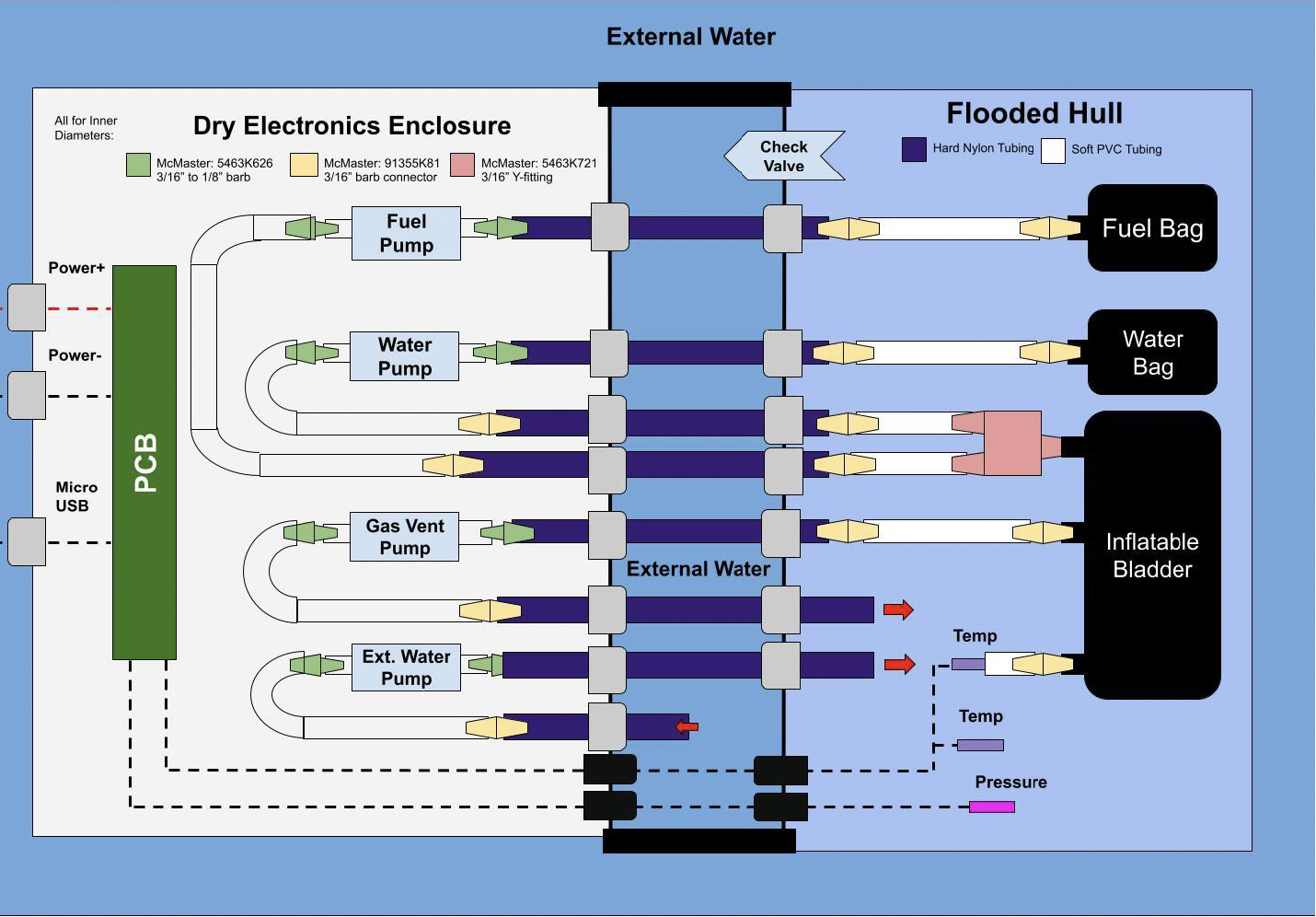

The prototype (above) is built around a dual-housing architecture consisting of a fully flooded hull and a sealed dry electronics enclosure. The flooded hull contains the aluminum fuel bag, water bag, and inflatable bladder, while the dry compartment houses the control electronics, sensors, and pump drivers. The two zones are connected through carefully sealed pass-throughs that maintain waterproofing while routing hard nylon tubing, soft PVC lines, check valves, and Y-junction fittings. This routing network manages water intake, reactant flow, gas venting, and bladder inflation, and its watertight performance was essential to ensuring stable operation under pressure.

To operate the fluid network, Calypso uses a set of custom-designed electronics.These circuits seen above allow the pumps to run reliably inside the underwater shell while isolating all sensitive components in the dry housing. Real-time sensing is handled by pressure and temperature probes whose data feed into a dedicated monitoring interface and a command dashboard that controls ascent, descent, and emergency abort sequences.

Calypso

A test Configuration for an Aluminum-Fueled Buoyancy Engine

Calypso is a buoyancy engine prototype that explores how chemical reactions can drive controlled motion in underwater environments. The system investigates the feasibility of using the exothermic aluminum–water reaction to produce hydrogen gas and heat as a means of modulating buoyancy without relying on heavy batteries or motorized actuators. When aluminum reacts with water, it releases hydrogen gas that expands a flexible bladder, increasing system volume and decreasing density. Venting the gas reverses the process, allowing the engine to descend. By coordinating injection, venting, and pressure regulation, Calypso creates a repeatable chemical-to-mechanical cycle of ascent and descent. My role in the team was in the design of the hull, aluminum bladder, and was also a part of the electronics and control team.

The heart of the system is the aluminum fuel bag, designed to contain the reaction while managing heat transfer through the surrounding flooded environment(test setup on the left). Bench-top experiments measured reaction temperature behavior for both aluminum paste and pellet fuels, validating thermal safety and confirming the reaction’s ability to generate more than enough gas to drive meaningful buoyancy change. Modeling and steady-state heat transfer analysis guided the selection of wall thickness and material properties to prevent overheating and ensure predictable inflation behavior.